Common Issues with Cartridge Heaters

- Heater removal: a cartridge heater will oxidize after many hours of operation and maybe difficult to remove. Consider drilling a through hole so the heater can be hammered out or choose a split sheath cartridge heater.

- Lubricants like graphite or silicone facilitate the insertion of the cartridge heater but can carbonize at higher temperature and then the heater will be really stuck.

- For process temperatures above 450 deg F, use high- temp lead wire and ceramic bead insulation. Or order the heater with an additional length of cold section.

- The location of the temperature sensor is very critical. If the sensor is too far from the heater, then the surrounding area's ability to dissipate the heat generated by the heater may be exceeded.

Split Sheath Cartridge Heaters

The split sheath design allows the independent, bilateral expansion of each half of the heater outward against the walls of the surrounding bore. This maximized metal to metal contact results in greatly improved heat transfer under normal fit conditions of .005" to .007". This design assures superior heat transfer, more uniform process heat, greater efficiency and a reduced consumption of electricity (.pdf). It is also a cost effective solution for repair works to avoid re-machining an existing bore.

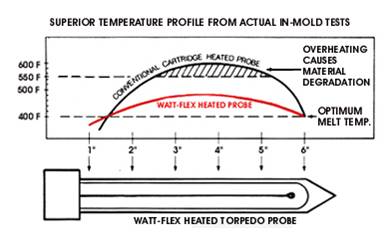

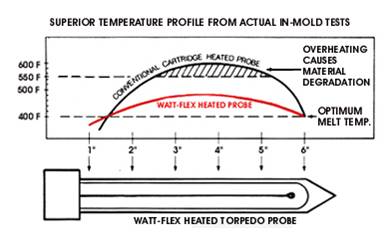

The split sheath design has a continuous heating coil which eliminates the cold spots which can occur at core junctions in ceramic core heaters. Uniform sheath temperature is vital when molding heat-sensitive plastics where the temperature window between gate freeze-off and material degradation is very narrow. By varying the

watt-density, the temperature profile may be customized to specific requirements. For example, applications requiring higher temperatures at the tip can be accomplished with split sheath heaters but not with conventional cartridge heaters.