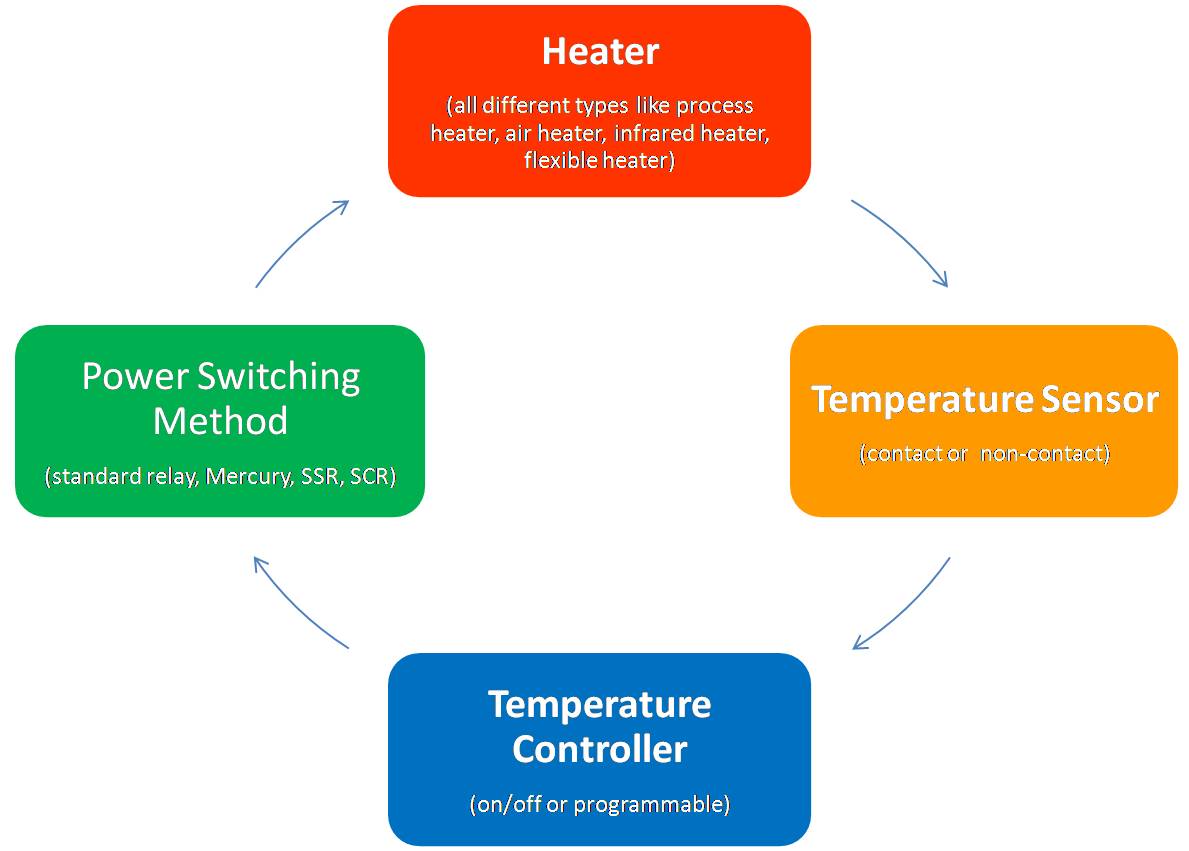

Elements of a Closed Loop Heat Cycle

In a closed loop temperature control system there is a constant feedback from the heater (or the part) through the which then in turns through a to maintain set point. This is sometimes also called a feed back control. In an open system, there is no such automatic feedback. No feedback requires constant attention from the operator or the result may be one you don't want. (like burning your food).

A closed loop temperature process control consists of (4) basic components:

- Heater element

- Temperature sensor

- Temperature controller

- Power switching device

The temperature sensor feeds this information to the temperature control, which then "calls" for more or less power delivered to the heater. It is important and helps save energy cost to properly match the characteristics of all four components.

Each of these elements are built in a wide variety of configurations:

Heaters

There are many, many different types of heaters. A common classification could be:

- Process Heaters (Band heater, Cartridge Heater, Circulation Heater, Immersion Heater, Strip Heater, Tubular Heater, Cast Heater)

- Air Heaters (Tubular Heater, Strip Heater, Hot Air tools, Duct Heater, Open-coil elements, Quartz Heater, Ceramic Heater)

- Radiant Heaters (Ceramic Heater, Flat Panel Heater, Quartz Lamps,T3 Lamps, Halogen Lamps, Tubular Metal Sheathed Heater)

- Flexible Heaters (Silicone Rubber Heater, Printed Circuit Heater, Thick Film Heater, Drum Heater, Kapton Heater, Heating Cable, Heating Bands)

Temperature sensors

Temperature sensor can be classified into two groups:

- Contact temperature sensors such as thermocouples, RTD and Thermistor.

- Non contact temperature sensors such as infrared sensors. Infrared sensors are also known as Pyrometer and Spectral Meter.

Temperature controllers

Temperature controller also come in a wide variety of configurations. The main groups are:

- On / Off control

- Controls with microprocessor's like PID controllers (example ETR 9090) or other controllers with so called "Fuzzy logic", which is mainly a marketing term.

Power switching devices

- Electromechanical relay

- Solid State Relay

- SCR (Silicon Controlled Rectifier)