General Description

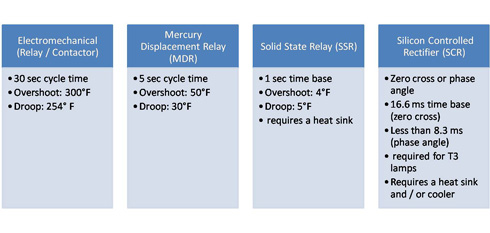

Today, in industrial heating applications, there are mainly three different types of relays used to switch power.

Electromechanical Relay

The main advantage is the relative low investment cost. The biggest drawbacks are the slow reaction time, limited life span and possible arcing. This type of relay is used where the heater doesn't need to be constantly turned on and off in less than 20 seconds.

Solid State Relay (SSR)

With no moving parts, this type of relay should be used where frequent power switching is required like in air heating and other low mass heaters. It is commonly mounted on a heat sink to dissipate the heat from the relay. Solid state zero cross contactors are commonly used as replacements for On / Off controls.

Silicon Controlled Rectifier (SCR)

This electronically controlled relay is available for single phase and 3-phase, zero cross firing and phase angle firing. A phase angle fired SCR can switch power in less than 10 millisecond. A phase angle fired SCR "must" be used for infrared heating applications (examples: furnaces, quartz infrared heaters, T3 lamps) and is also commonly used in the solar industry and heat treatment applications. We recommand to use a zero cross power controller for industrial air heating applications. see also FAQ about SCR power controller.

Mercury Displacement Relays are also still used today, but are losing on importance.

The output signal from the PID temperature controller (example: ETR 9090) needs to be matched to the input signal on the power controller.

|